Nigeria Sinotruk Local Sales Center 2025 Howo New Model

Nigeria Sinotruk Local Sales Center 2025 Howo New Model Nigeria Sinotruk Local Sales Center 2025 Howo New Model

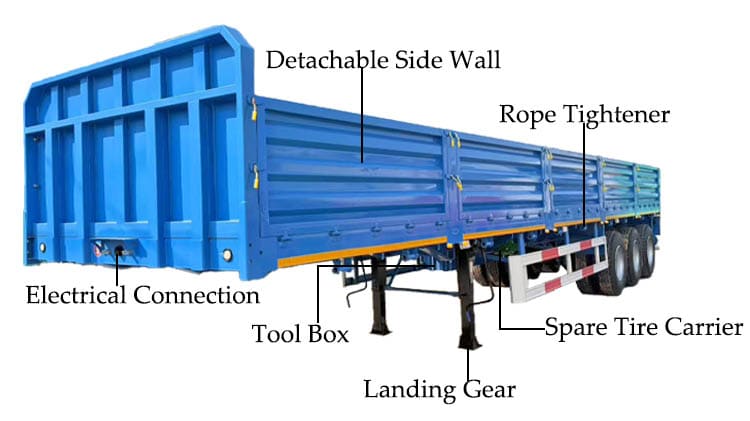

Nigeria Sinotruk Local Sales Center 2025 Howo New ModelThe cargo semi trailer is built to offer exceptional versatility, providing a dependable transport solution for a broad range of cargo types. Whether it’s construction supplies, machinery, or general freight, the dropside trailer accommodates varying transport requirements with efficiency and ease.

In the Nigeria market, the type of trailer has gained notable popularity due to its multifunctional nature and user-friendly design. Its ability to handle non-standard shaped loads and unpackaged bulk materials makes a practical choice for the diverse logistical challenges common in the region.

A standout feature is the inclusion of removable side panels. Both the sides and rear boards can be opened or detached according to operational needs, greatly improving efficiency during loading and unloading while reducing labor demands. The flexible configuration allows the sidewall cargo semi trailer to adapt quickly to different types of freight.

Dimension: 12500mm*2500mm*3200mm

Loading Capacity: 60 ton

Floor Plate: thickened pattern plate

Axles: 3 axles, 13 ton, TITAN brand

Leaf Spring: 10 layers

Suspension: mechanical suspension

Tire: 12R22.5, 12 units

Landing Gear: 28 ton

Lamp: LED lamp with net

For delivery and logistics, TITAN provides adaptable shipping solutions. Customers can choose between container transport and roll-on/roll-off (RORO) delivery based on the preferences and infrastructure availability.

Prior to shipping, each bulk cargo semi trailer is coated in protective wax and wrapped in a custom waterproof rain cover. The protective method shields the cargo semi trailer from the corrosive effects of sea spray, moisture, and salt—common risks during maritime transport—and helps ensure that each unit reaches Nigeria in excellent working condition.

The cargo semi trailer is finished in white and includes high-visibility elements that contribute to operational safety in various lighting and weather conditions. Unlike other usual paint methods, TITAN uses a powder spray coating process combined with baking painting.

The advanced method creates a strong bond between the paint and the steel surface, producing a coating that is more resistant to chipping, corrosion, and weather exposure. Even after extended use—five years or more—the coating remains vibrant and intact. Additionally, TITAN provides options for custom colors, giving Nigeria customers the ability to match the sidewall cargo semi trailer appearance to the branding or specific preferences.

The detachable sideboard structure plays a key role in reducing the bulk cargo semi trailer overall weight while improving cargo loading options. Compared to closed trailers, the detachable design offers increased space utility and easier access, which translates to improved loading rates and simplified cargo handling. The structure not only enhances operational flexibility but also helps lower ongoing maintenance and repair costs.

To support heavy transport demands, the sidewall cargo semi trailer frame is engineered for strength. The integration between the main beam and cross members ensures that the cargo semi trailer maintains structural reliability under heavy loading.

The cross members are made from 100mm thickened channel steel and reinforced with diagonal bracing. The braces are installed at intervals of no more than 500mm, ensuring the bulk cargo semi trailer load-bearing capacity is evenly distributed and that the frame resists bending or localized deformation under stress, critical for navigating Nigeria more challenging roads.

When comes to flooring, TITAN prioritizes cargo safety and durability. Rather than using smooth plates, which can allow bulk cargo to slip during transport, TITAN opts for high-strength patterned steel plates. These surfaces provide added friction, reducing the chance of cargo shifting in transit, while also boosting overall durability. The plates are also thickened to withstand significant loads and resist long term wear, further extending the sidewall cargo semi trailer operational lifespan under difficult conditions.

The TITAN cargo semi trailer suspension system is designed with resilience in mind. A reinforced mechanical suspension with a layered leaf spring setup helps absorb vibrations and jolts caused by potholes and uneven surfaces. All suspension parts are manufactured using high strength steel, giving the cargo semi trailer excellent impact resistance and thermal tolerance.

The suspension also includes a 70mm center balance pin and strengthened sections at key stress points across the frame. The design ensures that forces acting on the wheels are evenly distributed, reducing strain on the tires and helping the bulk cargo semi trailer maintain better road grip and balance during movement.

Add: PLOT 3, OBA, AKRAN AVENUE, IKEJA, LAGOS