Nigeria Sinotruk Local Sales Center 2025 Howo New Model

Nigeria Sinotruk Local Sales Center 2025 Howo New Model Nigeria Sinotruk Local Sales Center 2025 Howo New Model

Nigeria Sinotruk Local Sales Center 2025 Howo New ModelEvery component of TITAN's 4 axle lowboy trailer is designed with precision to ensure maximum stability, safety, and load-handling efficiency, making it a dependable solution for demanding heavy-haul transport operations. Continuous structural and functional improvements have made the rgn lowboy trailer particularly suitable for harsh working environments such as those in Nigeria, where uneven terrain, long-distance travel, and oversized cargo are common challenges.

4 Axle RGN Lowboy Trailer for Sale in Nigeria

4 Axle RGN Lowboy Trailer for Sale in Nigeria

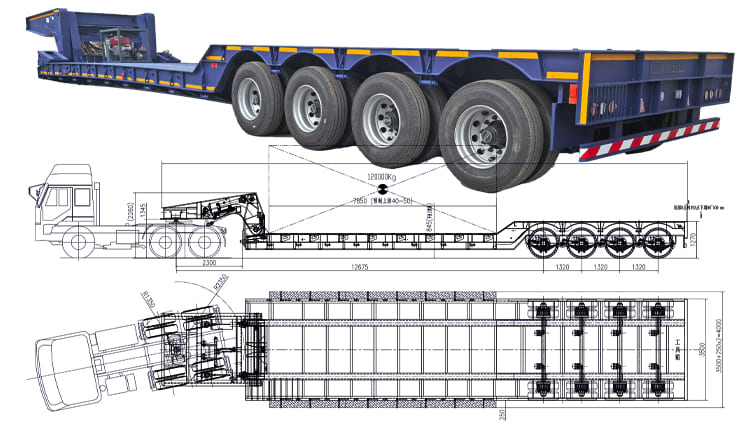

Dimension: 18135 mm*3500 mm*2300 mm

Loading capacity: 120 ton

Floor Plate: 5mm thick pattern plate

Side Beam: 300mm high

Ramp: foldable ramp

Gooseneck: removable gooseneck

Tire: 16 units

Leaf Spring: 10 layers

King Pin: JOST brand 90#

Axle: 16 ton

Light: LED light with net

TITAN also applies a dual-layer preservation process for international transportation of every 4 axle lowboy trailer. First, a specialized anti-corrosion wax coating is applied to all exposed surfaces. Then, the trailer is wrapped with a custom waterproof tarp to guard against seawater, moisture, and environmental exposure during shipping. This ensures every rgn lowboy trailer arrives in perfect working condition, ready for immediate use without additional preparations.

One defining characteristic of what many operators refer to as an rgn lowboy is its exceptionally low deck and open platform configuration. This structure greatly simplifies the loading of tall, wide, or heavy machinery and significantly lowers the center of gravity.

A lower center of gravity enhances overall balance during travel, reducing the risk of rollovers or lateral sway—an essential advantage when navigating unpaved or irregular road surfaces frequently encountered in Nigeria. With this layout, operators can move large industrial equipment through difficult areas without sacrificing safety or reliability.

The floor of the TITAN 4 axle lowboy trailer is built using 5mm-thick patterned steel plates. These plates are chosen for their excellent anti-slip properties and superior load-bearing strength. Their durability ensures cargo remains stable on long hauls, even when traveling across rough terrain or uneven pavement. This rugged flooring material plays a critical role in maintaining operational consistency and extending the service life of the rgn lowboy.

To protect the exterior of the rgn lowboy trailer from harsh environmental conditions, TITAN applies an advanced combination of powder coating and baking paint. This multi-layer finish provides outstanding resistance to corrosion, fading, and impact damage—an important benefit in Nigeria's variable climate, where humidity, heavy rainfall, and heat can accelerate wear. The protective coating reduces long-term maintenance needs and preserves the trailer's appearance and structural integrity.

Suspension performance is equally vital. The 4 axle lowboy trailer is equipped with reinforced leaf springs made from high-strength steel, engineered to absorb impacts from potholes and rough ground.

This design reduces vibration and shock transfer, ensuring better protection for both the trailer and the cargo. The improved suspension system enhances long-distance comfort, minimizes mechanical stress, and supports long-term durability—especially important on extended routes through remote regions.

For a secure connection between the towing truck and the rgn lowboy, TITAN uses a JOST 90# kingpin known for its reliability under heavy loads. This high-quality coupling component ensures stable handling and consistent towing performance across varied road conditions.

Braking efficiency is further enhanced with high-pressure rubber air lines, which offer greater resistance to wear and maintain powerful, consistent braking performance even after years of use.

The multi-axle design of the rgn lowboy trailer distributes weight evenly across all four axles, each rated at 16 tons. This balanced load distribution increases total payload capacity while preventing concentrated stress points or structural fatigue. Such a configuration is crucial when transporting massive machinery through rugged landscapes, such as those often found in Nigeria, where resilience and load stability are essential.

Safety is strengthened by the addition of rope tighteners along the sides of the rgn lowboy. These devices allow operators to secure cargo effectively, minimizing the risk of shifting during tight turns, steep grades, or sudden braking. Durable LED lighting with protective mesh covers provides bright illumination and reduces the chance of theft or damage, improving night-time visibility and operational safety in remote locations.

Add: PLOT 3, OBA, AKRAN AVENUE, IKEJA, LAGOS